What Is a CNC Turning Center?

What Is a CNC Turning Center?

A CNC Turning center is a more advanced adaptation of a very old process of machining, the lathe. This process holds the material within a clamping device called a “chuck” and rotates the chuck & material then introduces a static or counter rotating tool to the material, shaving off part of it until the desired shape and size is realized. Utilizing the function of a CNC (Computerized Numerical Controller) the tool can complete standard routines to turn, tap, thread and perform many other functions of the turning center. Often equipped with a bar feeder and parts catcher, the CNC turning Center is quickly and easily automated to provide hours of precision production requirements.

4 Types of CNC Turning Centers

CNC Turning as described above is the basis of the part rotation while a static or counter rotating cutter approaches on a controlled axis. Although there are many types of CNC turning centers that vary in design in order to accommodate a variety of specialty applications, they all rotate the material in the machining process. These designs are;

1. Horizontal: The horizontal CNC Turning center is by far the most popular design and is capable of most job shop applications handling the very small parts of ⅛” to over 30” in general. These machines are easily equipped with a myriad of options and accessories to allow them to be even more productive and capable.

2. Vertical: Often called the VTL (Vertical Turret Lathe) or VTC (Vertical Turning Center) the vertical design allows for larger parts (some massive) to use their weight in conjunction with clamping to rest upon a flat table like surface. These machines typically handle parts 30” and greater with some versions capable of turning parts weighing several tons and covering several building stories in size.

3. Inverse Vertical: Inverting the chuck from the flat position of the VTL to the vertical “hanging” position of a spindle-type machine allows some unique advantages. This design typically lends itself very well to machining castings or pre-cut parts where the automation needs to be accomplished for each individual part or slug. These machines can be automated with carousel parts stacker, conveyor belts and other robotics to assist in the loading and unloading of parts. Their inverse design helps remove the cut chips easily by gravity

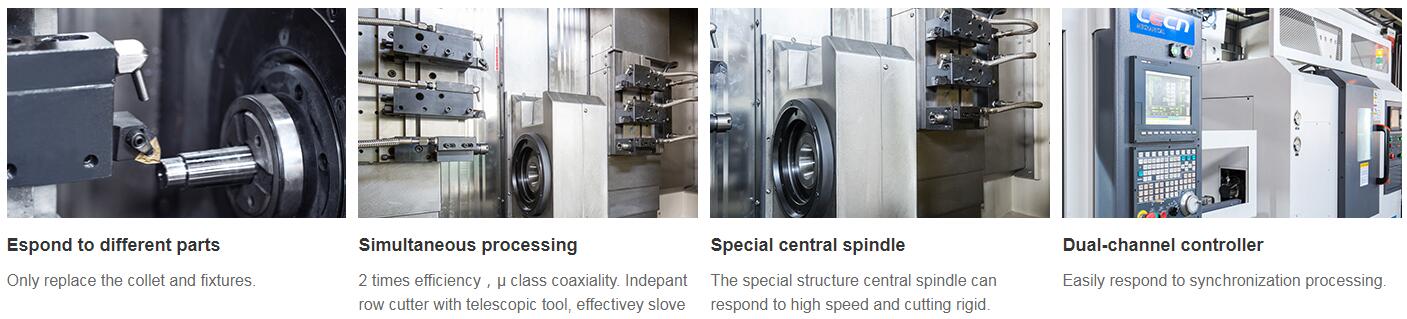

4. “Swiss” Type: In CNC Turning there is another machine we know as the “Swiss Type Lathe” but more correctly should be called the sliding headstock machine. Capable of very high production, these accurate machines can produce many parts very accurately in a short period of time. They are based on the Horizontal CNC Turning Center design as described previously but they add several unique features; first a headstock that slides the material through a synchronized rotating collet while multiple tools engage the workpiece at once leading to the highest levels of automation available in turning. Capable of milling, drilling, turning, tapping, and some unique processes like thread whirling the Swiss Style CNC Turning Center is definitely a popular choice.

评论

发表评论