7 Advantages of CNC Machining

Contents

● CNC machining produces little to no waste

● Faster and more efficient production

● Zero defects and higher accuracy

● Faster assembly

● Reduced energy consumption

● Enhanced personnel safety

● CNC machining can reduce production costs

● Conclusion

The fourth industrial revolution is about faster speeds, greater efficiency, and considerations of sustainability. In this context, automation will continue to play a key role in manufacturing activities, while modern, data-driven tools and equipment such as CNC lathes and CNC machining will drive innovation.

As a culmination of this high paced activity, precision turned parts will provide companies with a competitive advantage by enabling complex designs, introducing structural advantages and manufacturing parts that cannot be profitably replicated by any other manufacturing method. With that in mind, let's look at the various advantages that precision turned components offer.

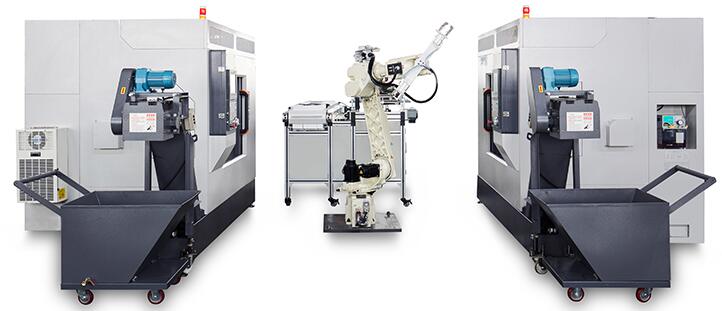

Double Head CNC Lathe+Joint Robot

CNC machining produces little to no waste

CNC machines run on an iteratively optimized software program that develops the best way to turn parts without waste. Such code may also be subject to simulation to check the validity of the management program prior to implementation.

Thus, the final CAD-CAM model will produce results and provide value from the first cycle, rather than a trial-and-error approach to design improvement.

In addition, because all precision milling machines run on repeatable software programs that use fixed tools along fixed routes, they can make clever use of the available raw materials. As a result, most highly advanced CNC machines can help manufacturers significantly reduce waste.

Faster, more efficient production

When using milling machines, it is possible to operate them at the fastest possible settings to meet the ever-increasing demand. In addition, as mentioned earlier, these machines can run 24 hours a day, 7 days a week, without fatigue, interruptions or trade-offs.

These facilities, combined with the fact that the machines will still maintain high precision and will not waste any material resources, make them one of the best ways to produce quickly, efficiently and scalably without any cost liability.

Zero defects and higher accuracy

Since precision lathes run automatically and without any human intervention, they bypass the possibility of human error creeping into the manufacturing process and causing defects. By controlling the code and software programs of the end-to-end process, the machines can provide higher accuracy without any defects.

In addition, these inputs remain virtually constant throughout the production process, cycle after cycle, unless intentionally changed, which also maintains the consistency of the final product. In addition, these machines can run for long periods of time without any interruptions, without affecting the quality of the work produced.

Faster assembly

By decoupling production capacity from the number of employees required, the efficiency of manufacturing units can be improved by shifting human resources to the assembly line. Manual assembly lines are known to be more efficient in high production environments and where product assembly is complex to the extent that it requires specialized skills that cannot be replicated by machines.

In addition, the high precision turning of components allows for seamless assembly of parts, which allows the assembly line to flow freely without any disruption.

Joint Cross Machine CZ821030/TZ820510

Reduced energy consumption

The oil and gas, petrochemical, aerospace, and automotive industries are known to be energy intensive due to the losses involved. However, the introduction of CNC machines allows them to remain scalable and precise without tying up excessive limited resources such as energy and labor.

In addition to injecting sustainability, they also try to save more energy by reducing any energy losses that may occur due to poor or improper planning.

Enhanced Human Safety

CNC machines isolate the machine from humans and mitigate risks that would otherwise arise.

These machines can operate without an operator, thus limiting the possibility of accidents and reducing the risk to life and limb. Modern CNC machines are so powerful that they can even change tools automatically! Even if the design has changed, it can be activated by changing the software without having to come into contact with the machine or a person.

As a result, human intervention is limited to a supervisory role, and they can remotely monitor the execution of software programs and preventive or reactive maintenance to avoid malfunctions, thus minimizing the need for involvement and making the workplace safer.

CNC machining can reduce production costs

Considering the above advantages, it is intuitive to conclude that precision turning of parts using CNC machines can significantly reduce production costs. First, it increases the efficiency and scalability of production and assembly without wasting material.

Likewise, it reduces energy consumption and saves on these recurring operating costs. At the same time, it alleviates any financial liability arising from accidents and incidents. All in all, this is one of the most comprehensive ways to make your operations cost-effective without compromising process or quality.

Conclusion

By far, it is clear that precision turned parts produced by CNC machines are far superior to manual parts. More importantly, they have a host of additional benefits that can provide companies with a competitive advantage, helping them stay ahead of the curve by leveraging differentiators such as high quality, zero defects, and low environmental impact.

评论

发表评论